NASHIK PLANT 2

ASSEMBLY PLANT

• Our newest plant in Nashik is also located in MIDC Ambad. It was established in December 2022. Here we have built enhanced capacities for our customer Mahindra scorpio cargo export models.

PRESS SHOP & ASSEMBLY PLANT

This plant is probably the largest cargo manufacturing plant in the country today where roll formed panels, pressed parts and sub-assemblies are all under one roof. The plant's product portfolio consists of floors, front doors, back doors, fenders and load body cargo production. The semi-automated process boosts the production process in the Light and Heavy press shop.

ASSEMBLY PLANT

• Our newest plant in Nashik is also located in MIDC Ambad. It was established in December 2022. Here we have built enhanced capacities for our customer Mahindra scorpio cargo export models.

DIE DESIGN & MANUFACTURING

Our in-house die design and manufacturing unit includes the complete suite of CAD/CAM/CAE software tools along with a machining set up of CNC, VMC and plano-milling. We also have a 5 axis laser cutting machine, wire cutting machine and try out presses here.

FORGING UNIT

We also have a vertically integrated forging unit which is also located in Ambad MIDC, Nashik. The unit includes fleshless forging, CNC billet Cutting, in-house normalizing, short blasting, electric billet heating, complete inspection & testing facilities. This unit has a capacity of press forging up to 7kg parts and a 6 inch horizontal forging press.

PRESS SHOP & ASSEMBLY PLANT

• The Press Shop, spread over an area of 5 acres, is one of the most technologically advanced production plants in India. Apart from the conventional press line with 1500T Header Press and robotic weld lines the plants also have SPMs and low cost automation designed and developed by us in-house. • Here we also have a fabrication set-up for axels and suspensions as well as a manufacturing line for trailer subassemblies that are exported to Germany.

ASSEMBLY SHOP

• This is a pressing and assembly unit where we manufacture door sash, which is the most critical sheet metal part that goes into assembling a car. It requires top-notch sheet metal roll forming, stretch bending, welding and highly skilled metal finishing under close tolerance.

CED COATING & PAINTING FACILITY

This facility has the capacity of coating 100 bodies per day and body height of 2.5 meter and length of 8 meters.

ASSEMBLY PLANT AT MVML VENDOR PARK

Redefining innovation since 2005 is our state-of-art Mahindra Vehicle Manufacturers Ltd. Supplier Park Plant. It consists of an assembly and weld shop that supplies load bodies, sheet metal chassis and Body-in-White parts solely to Mahindra Vehicle Manufacturing Ltd.

ASSEMBLY PLANT

• Our 5th plant in Chakan, Pune was established in January 2023. Here we have a set up for chassis frame as well as ERW manufacturing. Check the drop down section in our business portfolio tab for details on the manufacturing set-up.

HEAVY FABRICATED & MACHINED ASSEMBLIES

Mungi Metalcraft LLP is a Mungi Group subsidiary. Our latest state of art facility is located on a 8 acre plot in Chakan MIDC. Here we are manufacturing heavy fabricated and machined assemblies using high thickness steel for the construction equipment, infrastructure as well as wind energy industries. Check the drop down section in our business portfolio tab for details on the manufacturing set-up.

PRESS SHOP, ASSEMBLY SHOP & PAINT BOOTH

The plant consists of shop floor covering a massive area of 2 Lakh sq. ft. The plant has a press shop, assembly weld lines and a tool room for tool and fixture maintenance. We also manufacture 3-wheeler body in white, critical welded assemblies and press parts. We have successfully set up a state of the art manufacturing line for assembling Rotovators for Mahindra AppliTrac. We have also developed a Tractor Trolley completely in-house which can be manufactured here.

PRESS SHOP & ASSEMBLY PLANT

This plant is probably the largest cargo manufacturing plant in the country today where roll formed panels, pressed parts and sub-assemblies are all under one roof. The plant's product portfolio consists of floors, front doors, back doors, fenders and load body cargo production. The semi-automated process boosts the production process in the Light and Heavy press shop.

ASSEMBLY PLANT

• Our newest plant in Nashik is also located in MIDC Ambad. It was established in December 2022. Here we have built enhanced capacities for our customer Mahindra scorpio cargo export models.

DIE DESIGN & MANUFACTURING

Our in-house die design and manufacturing unit includes the complete suite of CAD/CAM/CAE software tools along with a machining set up of CNC, VMC and plano-milling. We also have a 5 axis laser cutting machine, wire cutting machine and try out presses here.

FORGING UNIT

We also have a vertically integrated forging unit which is also located in Ambad MIDC, Nashik. The unit includes fleshless forging, CNC billet Cutting, in-house normalizing, short blasting, electric billet heating, complete inspection & testing facilities. This unit has a capacity of press forging up to 7kg parts and a 6 inch horizontal forging press.

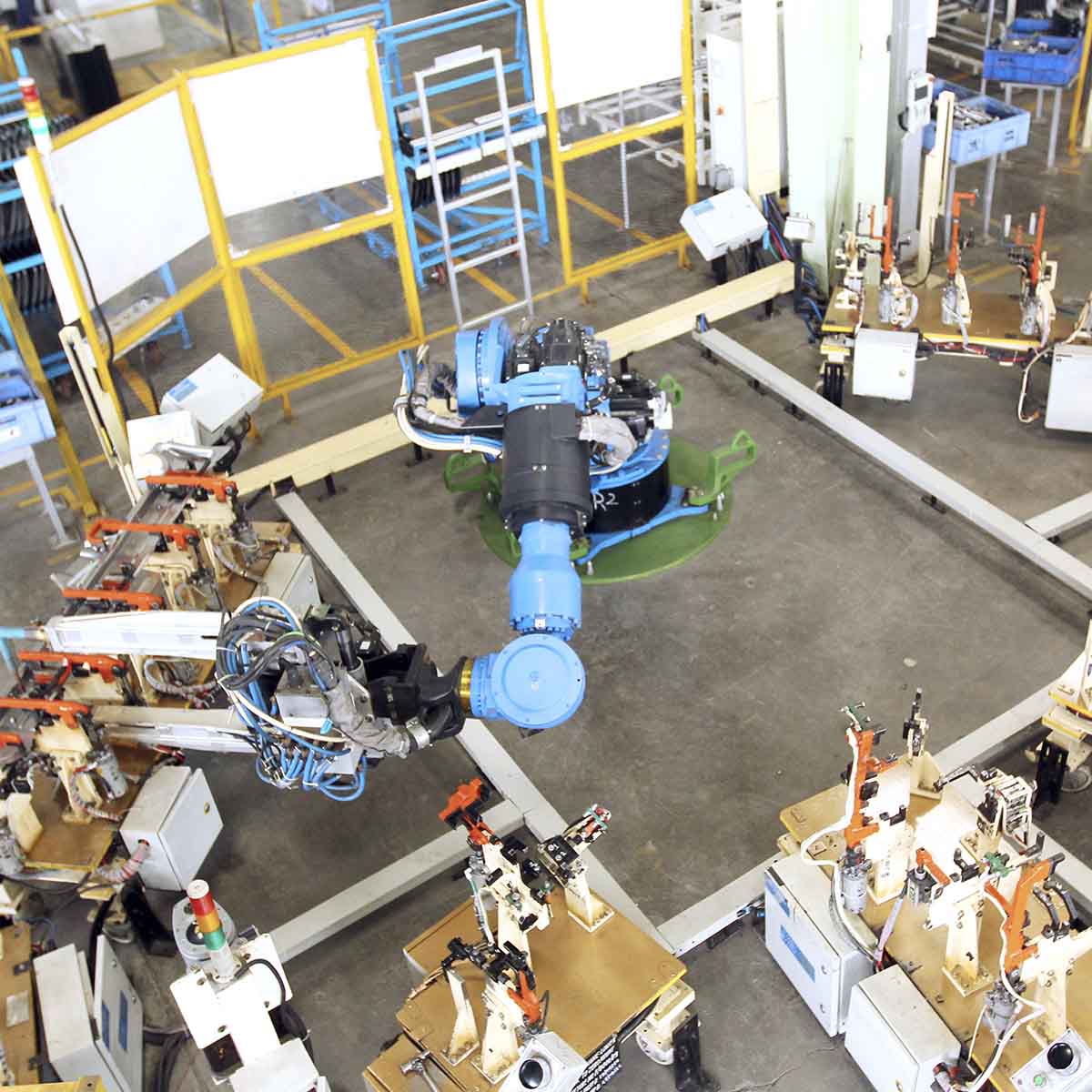

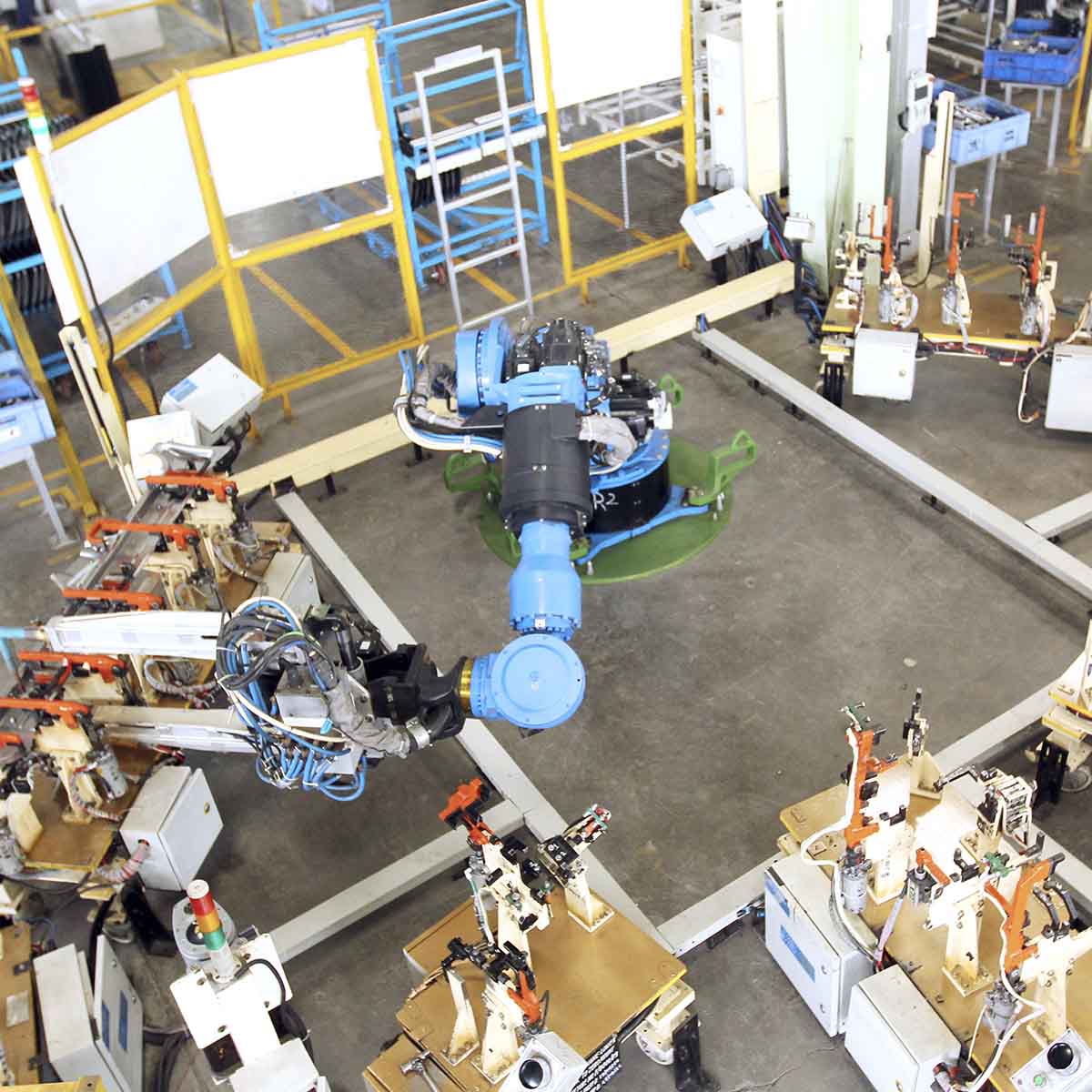

PRESS SHOP & ASSEMBLY PLANT

• The Press Shop, spread over an area of 5 acres, is one of the most technologically advanced production plants in India. Apart from the conventional press line with 1500T Header Press and robotic weld lines the plants also have SPMs and low cost automation designed and developed by us in-house. • Here we also have a fabrication set-up for axels and suspensions as well as a manufacturing line for trailer subassemblies that are exported to Germany.

ASSEMBLY SHOP

• This is a pressing and assembly unit where we manufacture door sash, which is the most critical sheet metal part that goes into assembling a car. It requires top-notch sheet metal roll forming, stretch bending, welding and highly skilled metal finishing under close tolerance.

CED COATING & PAINTING FACILITY

This facility has the capacity of coating 100 bodies per day and body height of 2.5 meter and length of 8 meters.

ASSEMBLY PLANT AT MVML VENDOR PARK

Redefining innovation since 2005 is our state-of-art Mahindra Vehicle Manufacturers Ltd. Supplier Park Plant. It consists of an assembly and weld shop that supplies load bodies, sheet metal chassis and Body-in-White parts solely to Mahindra Vehicle Manufacturing Ltd.

ASSEMBLY PLANT

• Our 5th plant in Chakan, Pune was established in January 2023. Here we have a set up for chassis frame as well as ERW manufacturing. Check the drop down section in our business portfolio tab for details on the manufacturing set-up.

HEAVY FABRICATED & MACHINED ASSEMBLIES

Mungi Metalcraft LLP is a Mungi Group subsidiary. Our latest state of art facility is located on a 8 acre plot in Chakan MIDC. Here we are manufacturing heavy fabricated and machined assemblies using high thickness steel for the construction equipment, infrastructure as well as wind energy industries. Check the drop down section in our business portfolio tab for details on the manufacturing set-up.

PRESS SHOP, ASSEMBLY SHOP & PAINT BOOTH

The plant consists of shop floor covering a massive area of 2 Lakh sq. ft. The plant has a press shop, assembly weld lines and a tool room for tool and fixture maintenance. We also manufacture 3-wheeler body in white, critical welded assemblies and press parts. We have successfully set up a state of the art manufacturing line for assembling Rotovators for Mahindra AppliTrac. We have also developed a Tractor Trolley completely in-house which can be manufactured here.